MHD Maschinenservice

Recondition of Gear cutters

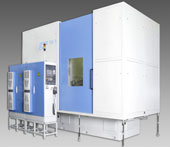

Complete remanufacturing with upgrade to NC control Siemens 840 D

MHD restores and remanufactures gear hobbers and gear shapers from the manufacturers Pfauter and Modul. Reconditioning of machines for job sizes 250 mm to 3150 mm takes place in our company, bigger machines remain at the customers location and the rebuild takes place there.

The scope of a remanufacturing process of a conventional machine and conversion into a NC gear hobber with Siemens 840D contains of removal of the whole kinematics of the machine, exchange of all bearings and sealing elements, replacement of trapezoidal spindles by ball screws and rescraped / ground guideways. With newly designed drive systems adapted to the existing subassemblies and machine parts all mechanical gear boxes are obsolete.

We do reconditioning works only with our qualified and experienced personnel. After remanufacturing the machine features an NC control with adapted diagloue menue and it is almost a new one. This applies also to safety features in compliance with CE regulations. We prove the quality of our workmanship during the machine acceptance by measuring of finished jobs on our NC gear inspection machine.

If modifications for less than 6 axes are desired then remanufacturing and upgrade to three NC axes is also possible, in that case index change gears and part of the kinematics remain in the machine.