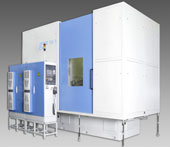

Bevel gear generator for straight bevel gears KFG 320

The machine is suitable for generation of straight bevel gears up to diameter 315 (350) mm and module 10,

max gear face width is 50 mm.

The machine provides high productivity because it features two direct cutting spindles for heavy duty cutting.

The cutter spindles have gearless drives. The two cutter heads in disc shape with single blades are engeaged and generate involute tooth flanks.

The position of the contact pattern on the flanks is symmetric related to the tooth height. (Konvoid principle) Because of the two cutter heads both tooth flanks are completed in one cycle.

Applications for bevel gears with straight flanks are in machines for agriculture, mining, differential gear boxes for trailers, automotive and machine tools. Due to shortes setting - and cycle times the machine is both suitable for small batch production and mass production.

More machine features:

- Rigid construction design for machine bed, tool colum and workpiece column

- precision guideways for tool and workpiece column

- central opening in the machine bed for efficient chip removal

- latest state of the art technologies for the drives (torque motors)

- linear and rotary scales Heidenhain and Renishaw

- MHD - operator interface on Sinumerik 840D sl

- Tool application: coated HSS single blades and carbide inserts

Short setting times of the machine by means of:

- Exchange of completely tooled cutter heads

disconnection of the constant synchronisation of the two cutter heads and retraction of the upper cutter

spindle, after that exchange of the completed cutter heads

mounting of the single blades in the cutter heads and runout checks of the completed cutter heads

outside the machine - machine setup values are calculated quickly in our software after input of parameters related to tools

and workpiece, then the NC axes approach their calculated starting position automatically - A convenient operator interface enables 1uick amd easy corrections

Following working cycles are available in the software:

- plunge cutting cycle

- completing of bevel gears

- completing of pinions

- generating cycle

- plunge cut generating cycle

KFG 320 - Bevel gear generator for straight bevel gears

with NC control Sinumerik 840D sl / Konvoid method

| Max. diameter of work at ratio 1:6 Max. diameter of work at ratio 1:1 Max. module Max. gear face width number of teeth speed range of tool spindle Max. infeed rate Max. generating feed rate max. power of cutter heads | 315 mm 225 mm 10 mm 50 mm 6 - 100 35 – 310 min-1 8 m/min 30 Grad/s 2x 11,0 kW |

Cutter heads and blades

| Fixtures for workpieces

|

More details of the specification and technical data are available here

Werkstücke / work pieces

|  |  |  |  |